The Latest in SMD Technology: Benefits and Applications

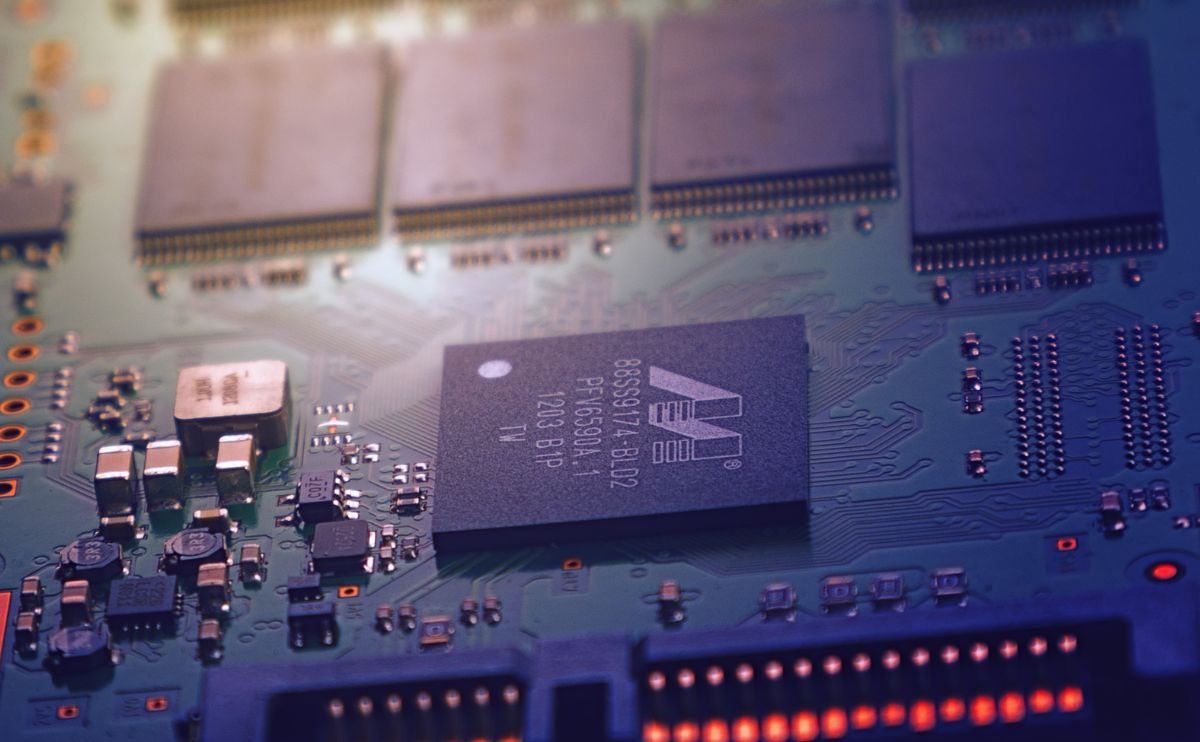

Surface-Mount Technology (SMT) has revolutionized the electronics industry by enabling the creation of compact, efficient, and reliable electronic devices. Surface-Mount Devices (SMDs) are at the heart of this innovation, making them indispensable in modern electronics. This article explores the latest advancements in SMD technology, its benefits, and its diverse applications across industries.

What is SMD Technology?

Surface-Mount Devices are electronic components designed to be mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components that require leads to pass through holes in the PCB, SMDs are soldered onto the surface, reducing size and weight. This method has become the standard for manufacturing compact and high-performance electronics.

Latest Advancements in SMD Technology

- Miniaturization of Components The trend towards smaller devices continues, with SMDs shrinking in size while maintaining or even improving functionality. This miniaturization is crucial for wearables, smartphones, and IoT devices.

- Improved Thermal Management Modern SMDs incorporate better heat dissipation mechanisms, enabling them to handle higher power levels without overheating. Advanced materials and designs help enhance performance and longevity.

- High-Density Packaging Advances in packaging technologies allow for more components to be placed on smaller PCBs, increasing functionality without increasing size.

- Lead-Free Soldering The shift to environmentally friendly, lead-free soldering materials ensures compliance with global regulations such as RoHS (Restriction of Hazardous Substances), making SMD technology more sustainable.

- Advanced Assembly Techniques Automation in SMD assembly, such as pick-and-place machines with AI integration, has improved precision and efficiency, reducing manufacturing defects.

Benefits of SMD Technology

- Compact Design SMDs enable the production of smaller, lighter devices, ideal for portable electronics and space-constrained applications.

- Enhanced Performance The shorter lead lengths of SMDs reduce parasitic inductance and capacitance, improving signal integrity and performance in high-frequency applications.

- Cost-Effective Manufacturing Automated assembly processes for SMDs reduce labor costs and production time while maintaining high precision.

- Reliability and Durability The robust design of SMDs offers better resistance to mechanical stress and environmental factors compared to traditional through-hole components.

- Versatility SMDs are available in a wide range of types, including resistors, capacitors, diodes, transistors, and ICs, catering to diverse applications.

Applications of SMD Technology

- Consumer Electronics SMDs are integral to smartphones, laptops, tablets, and wearable devices, enabling their sleek and lightweight designs.

- Automotive Industry Advanced driver-assistance systems (ADAS), infotainment systems, and engine control units heavily rely on SMDs for their compact and reliable performance.

- Medical Devices From portable diagnostic tools to implantable devices, SMDs enable the development of miniaturized and precise medical equipment.

- Industrial Automation SMDs power sensors, controllers, and communication modules in industrial automation systems, ensuring reliability and efficiency.

- Aerospace and Defense High-performance and compact SMDs are used in avionics, communication systems, and navigation equipment, where size and reliability are critical.

- Internet of Things (IoT) IoT devices, such as smart home gadgets and environmental sensors, leverage SMD technology for their small form factors and high integration capabilities.

The Future of SMD Technology

As the demand for compact and high-performance devices grows, SMD technology will continue to evolve. Innovations such as flexible SMDs, advanced materials, and AI-driven manufacturing will drive the next wave of advancements. These developments promise even greater efficiency, reliability, and versatility, ensuring that SMDs remain at the forefront of electronic innovation.

Conclusion

Surface-Mount Technology has transformed the electronics industry, making modern gadgets more compact, efficient, and reliable. With continuous advancements in SMD technology, the possibilities for innovation are endless. Whether you’re a hobbyist, an engineer, or a business owner, understanding SMDs and their applications is key to staying ahead in the ever-evolving world of electronics